Inventory Tracking Management: Choosing the Right System

-

December 11, 2025

-

6 min read

How to Choose the Right Inventory Tracking Management System for Your Business

As businesses grow, keeping tabs on assets, inventory, and shipments becomes increasingly complex. An efficient inventory tracking management system is no longer a nice-to-have—it’s a must-have for maintaining operational visibility, preventing losses, and ensuring customer satisfaction.

But with a plethora of inventory tracking system software options available, how do you select the one that best fits your business needs?

In this article, we’ll walk you through the critical decision factors for choosing an inventory tracking management solution, including:

- Assessing your business requirements.

- Evaluating tracking technologies.

- Considering data analytics and automation capabilities.

- Ensuring scalability and cost-effectiveness.

Assessing Your Business Requirements

The first step in selecting inventory tracking system software is to identify your specific business needs:

- Nature of Assets/Inventory: Do you need to track fixed assets, vehicles, perishable goods, or high-value items? Each category has unique monitoring requirements. For example:

- Perishables need temperature and humidity tracking.

- Electronics require anti-theft features.

- Vehicles need GPS location monitoring.

- Operational Scale: The size and complexity of your operations directly impact the robustness and scalability needed in your tracking system. Consider factors like:

- Number of warehouses and locations.

- Volume of assets and inventory.

- Complexity of supply chain network.

- Compliance Needs: Regulated industries such as pharmaceuticals, food, and aerospace have stringent tracking and reporting requirements. Your system must support:

- Cold chain monitoring.

- Tamper alerts and audit trails.

- Adherence to industry standards like GMP and HACCP.

Evaluating Tracking Technologies

The next step is to assess the suitability of different tracking technologies for your business scenario:

RFID vs. Barcode vs. IoT Sensors

- RFID (Radio Frequency Identification): Ideal for bulk scanning and tracking assets within a facility. RFID tags can be read simultaneously, enabling rapid inventory updates.

- Barcodes: A cost-effective option for item-level tracking, but they require line-of-sight scanning and manual labor.

- IoT Sensors: Enable remote, real-time monitoring of location, motion, temperature, humidity, and more. IoT is crucial for tracking dynamic, mobile assets across complex supply chains.

GPS & Geofencing

GPS tracking is essential for monitoring vehicles and shipments in transit, providing live location updates. Geofencing allows you to set virtual boundaries and receive alerts when assets enter or exit designated areas, helping prevent unauthorised movement and theft.

Integration Capabilities

Your inventory tracking system software must seamlessly integrate with your existing ERP, warehouse management system (WMS), and transportation management system (TMS). This enables automated data flow, minimises manual errors, and provides a unified view of your inventory across the supply chain.

Considering Data Analytics & Automation

Advanced inventory tracking management systems go beyond basic monitoring, offering powerful analytics and automation capabilities:

- Real-Time Visibility: Cloud-based platforms provide instant access to live inventory data, enabling quick responses to disruptions or discrepancies.

- Advanced Analytics: Features like demand forecasting, automated replenishment, and predictive maintenance use AI and historical data to optimise inventory levels and prevent stockouts.

- Automated Alerts: Real-time notifications for exception events, such as temperature breaches or unauthorised access, allow proactive issue resolution.

Ensuring Scalability & Cost-Effectiveness

As your business expands, your inventory tracking system software must scale to handle increased asset volumes and new locations without performance degradation. Cloud-based solutions offer easier scalability compared to on-premise systems.

Evaluate the total cost of ownership, including hardware, software, integration, and maintenance, against the long-term benefits of improved efficiency, loss prevention, and customer satisfaction. While more advanced systems may have higher upfront costs, their ROI often justifies the investment.

Vendor Reliability & Support

Choose a vendor with proven expertise and success stories in your industry. Evaluate their technology roadmap, financial stability, and customer support infrastructure. Ensure they offer implementation services, user training, and ongoing technical support to drive successful adoption.

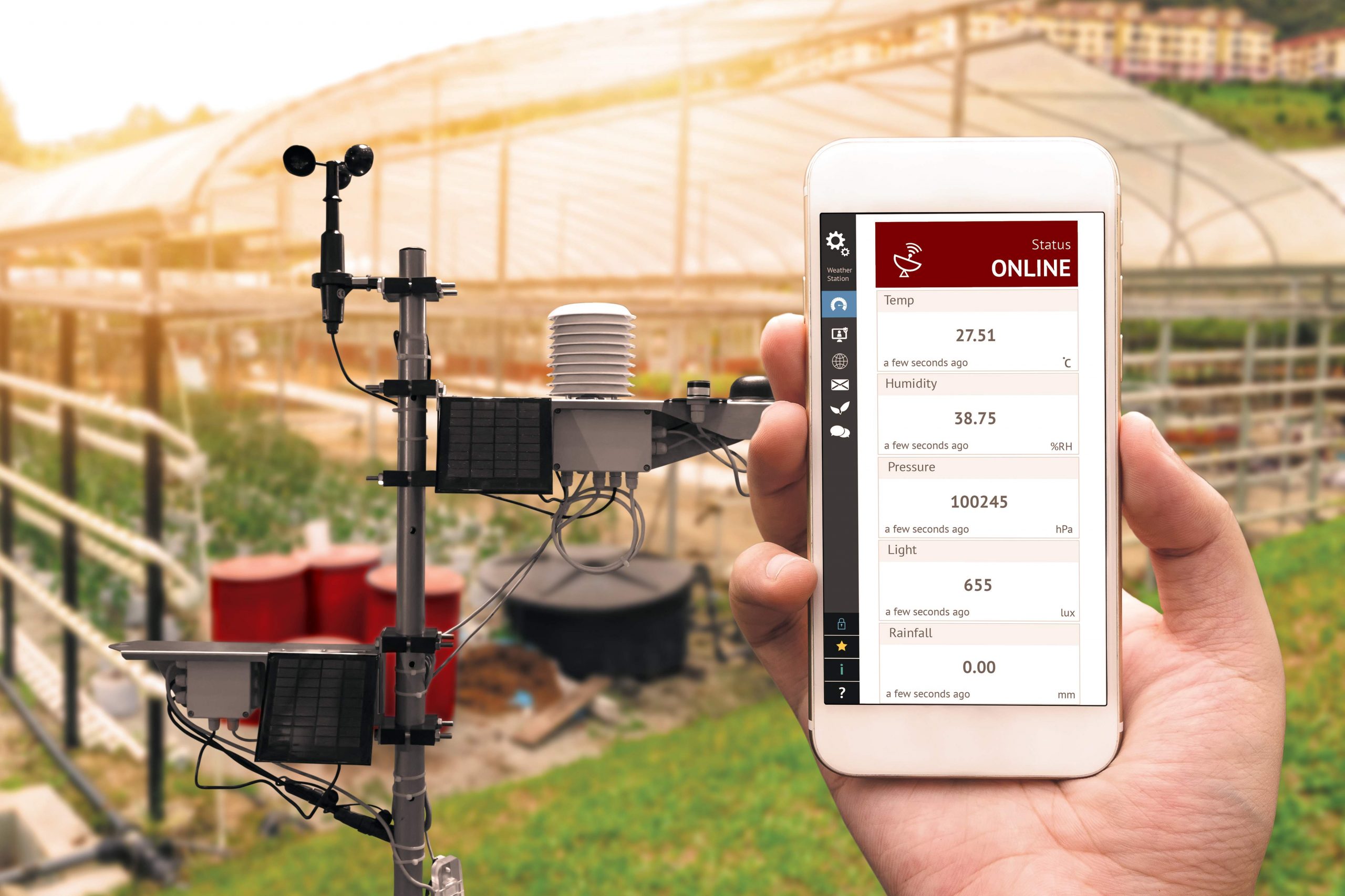

Real-World Use Case: IoT-Enabled Cold Chain Monitoring

Let’s consider a pharmaceutical exporter in India. Maintaining strict temperature control is critical to prevent spoilage of sensitive drugs during transit. By implementing an IoT-based inventory tracking management system like Airtel IoT Super Tracker, they can:

- Monitor Temperature and Humidity in Real-Time Across Multiple Shipments

Small IoT sensors are placed inside each shipping container, continuously collecting and transmitting data on temperature and humidity. This allows logistics managers to have a live, centralised dashboard showing the exact conditions of every shipment, no matter where it is—from a warehouse in India to a port on the other side of the world.

- Receive Instant Alerts for Any Temperature Excursions

The system is pre-configured with a specific temperature range, and if the temperature goes outside of this range for even a short period, it immediately triggers an alert. This could be an SMS, an email, or a notification to a mobile app, allowing the team to take immediate action, like checking the refrigeration unit, and potentially saving the entire shipment.

- Maintain Audit Trails and Compliance Reports

The IoT system automatically logs all sensor data, creating a secure and unchangeable digital record for every shipment. This detailed log includes timestamps, locations, and all temperature readings, which is essential for proving compliance with international regulations and providing verifiable evidence during audits or in case of a product dispute.

- Optimise Routes and Logistics Based on Performance Analytics

Over time, the data collected from all shipments can be analysed to identify trends and inefficiencies. This helps the company pinpoint issues like specific routes that frequently experience temperature spikes or shipping partners with unreliable cold chain performance, enabling them to make data-driven decisions to improve their logistics processes and overall efficiency.

Such visibility and control help minimise losses, ensure product integrity, and comply with stringent regulations.

In a Nutshell

Choosing the right inventory tracking system software is a strategic decision that directly impacts your operational efficiency, customer experience, and bottom line. By carefully evaluating your business requirements, comparing available technologies, and partnering with a reliable vendor, you can implement a solution that scales with your growth and delivers measurable ROI.

Airtel IoT Super Tracker is a future-proof choice for inventory tracking management, offering a comprehensive suite of IoT-powered monitoring capabilities, advanced analytics, and seamless integration with business systems. With its scalable architecture, rapid deployment, and 24/7 support, Airtel IoT Super Tracker empowers businesses to optimise their inventory, prevent losses, and unlock new levels of supply chain efficiency.

Share

Share