How IIoT is Redefining the Future of Smart Factories in Industry 4.0

-

April 7, 2025

-

6 min read

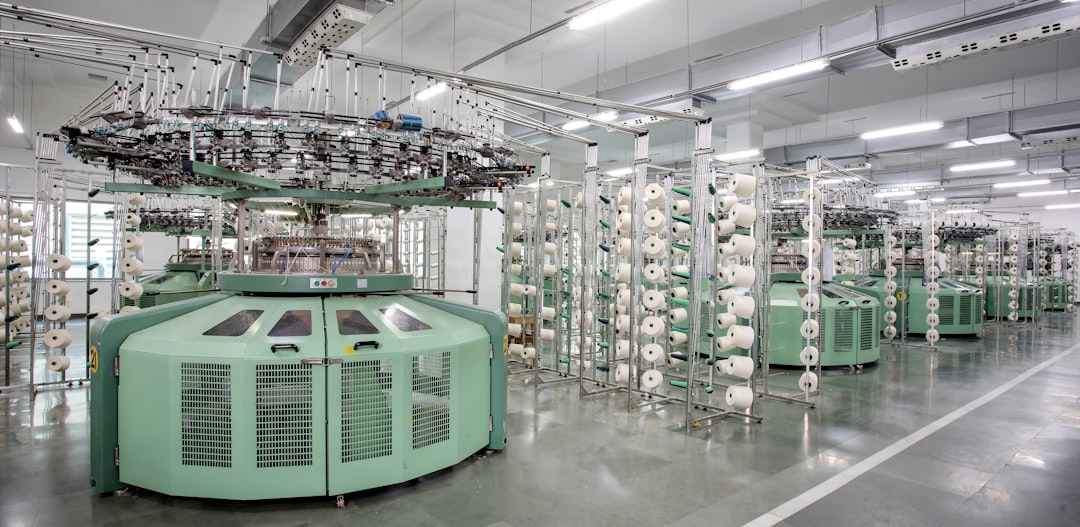

The fourth industrial revolution, or Industry 4.0, is transforming traditional manufacturing into highly automated, data-driven smart factories. At the heart of this transformation lies the Industrial Internet of Things (IIoT), a network of connected devices, sensors, and machines that enable real-time monitoring, analysis, and optimisation of production processes. As factories embrace IIoT technologies, they unlock unprecedented levels of efficiency, flexibility, and quality control. Let’s explore how Industrial IoT is reshaping the manufacturing landscape and creating the smart factories of the future.

Industrial Internet of Things IoT: The Backbone of Smart Factories

At its core, the Industrial Internet of Things IoT is a network of interconnected devices, sensors, and machines that collect, exchange, and analyse data in real-time. In the context of smart factories, IIoT forms the backbone of a highly automated and intelligent production ecosystem.

Key Components of IIoT in Smart Factories

- IoT Devices and Sensors: Smart factories are equipped with a myriad of IoT devices and sensors that monitor various aspects of the production process, from machine performance to environmental conditions. These devices generate vast amounts of data that forms the foundation for real-time decision-making and optimisation.

- Connectivity Infrastructure: Robust and reliable connectivity is essential for seamless data exchange between devices, machines, and systems. Industrial-grade networks, such as Airtel IoT Connectivity, ensure secure and low-latency communication, enabling real-time data transmission and analysis.

- Cloud Computing and Big Data Analytics: The data generated by IIoT devices is often processed and analysed in the cloud using advanced big data analytics tools. This allows for real-time insights, predictive maintenance, and optimisation of manufacturing processes.

- Artificial Intelligence and Machine Learning: AI and ML algorithms play a crucial role in making sense of the vast amounts of data generated by IIoT devices. They enable predictive analytics, anomaly detection, and autonomous decision-making, driving efficiency and quality in smart factories.

Benefits of IIoT in Smart Factories

The adoption of Industrial Internet of Things IoT in smart factories brings a multitude of benefits that transform the manufacturing landscape:

1. Enhanced Automation and Productivity with Industrial IoT

One of the key benefits of Industrial Internet of Things IoT in smart factories is the ability to automate processes and improve productivity. By connecting machines, sensors, and devices, IIoT enables seamless communication and coordination between different parts of the production line. This allows for:

- Real-time monitoring and control of equipment

- Automated material handling and inventory management

- Optimised production scheduling and resource allocation

For example, Siemens’ Amberg factory in Germany, a model of Industry 4.0, uses IIoT sensors and AI algorithms to optimise production processes in real-time. This has resulted in a 75% automation rate and a 99.9988% perfect product quality rate.

2. Predictive Maintenance Powered by Industrial IoT

Industrial IoT sensors can continuously monitor the health and performance of machines, collecting data on vibration, temperature, and other key parameters. By analysing this data using machine learning algorithms, smart factories can:

- Predict when equipment is likely to fail

- Schedule maintenance proactively to prevent downtime

- Extend the lifespan of machines and reduce repair costs

A study by McKinsey highlights how predictive maintenance, enabled by IIoT, can reduce maintenance costs by up to 40% and decrease equipment downtime by up to 50%.

3. Data-Driven Decision Making with Industrial Internet of Things

Industrial Internet of Things IoT generates vast amounts of data from connected devices and sensors. By leveraging advanced analytics and AI, smart factories can turn this data into actionable insights for better decision-making. Some examples include:

- Identifying bottlenecks and inefficiencies in the production process

- Optimising energy consumption and reducing waste

- Improving product quality and yield

With real-time visibility into operations, managers can make informed decisions to drive continuous improvement and stay competitive in the market.

4. Flexible and Agile Manufacturing through Industrial IoT

Industrial IoT enables smart factories to be more flexible and agile in responding to changing customer demands. By connecting machines and systems, IIoT allows for:

- Rapid reconfiguration of production lines

- Customisation of products at scale

- Efficient handling of small batch sises

This flexibility is crucial in today’s fast-paced market, where consumers expect personalised products delivered quickly. With IIoT, manufacturers can meet these demands while maintaining efficiency and profitability.

5. Enhanced Safety and Security in Industrial IoT Smart Factories

Industrial Internet of Things IoT can significantly improve safety and security in manufacturing facilities. By monitoring the factory environment and worker activities, IIoT sensors can:

- Detect potential hasards and alert workers in real-time

- Ensure compliance with safety regulations

- Prevent unauthorised access to sensitive areas

In addition, IIoT enables secure communication between devices and systems, protecting sensitive data from cyber threats. This is crucial as smart factories become more connected and digitised.

In addition, by optimising resource utilisation, reducing waste, and minimising downtime, IIoT helps manufacturers achieve significant cost savings. Predictive maintenance alone can lead to substantial reductions in maintenance costs and increased equipment uptime.

Real-World Case Studies

Let’s look at some real-world examples of how Industrial Internet of Things IoT is transforming smart factories:

- BMW’s Smart Factory: BMW’s smart factory in Germany utilises IIoT to create a highly automated and connected production environment. IoT sensors monitor every aspect of the production process, from welding to painting, enabling real-time optimisation and quality control.

- GE’s Brilliant Factory: GE’s brilliant factory concept leverages IIoT to create a digitally connected and optimised manufacturing ecosystem. By integrating IoT devices, data analytics, and AI, GE has achieved significant improvements in efficiency, quality, and agility across its manufacturing operations.

Conclusion

The Industrial Internet of Things IoT is changing smart factories, and bringing in a new era of efficiency, productivity, and innovation in manufacturing. By leveraging IoT devices, data analytics, and AI, smart factories are optimising production processes, improving quality, and driving cost savings.

As the manufacturing landscape continues to evolve, it is essential for businesses to embrace IIoT and adapt to the changing dynamics of Industry 4.0. Airtel IoT Connectivity management platform solutions provide a robust and reliable infrastructure for IIoT deployment, enabling manufacturers to unlock the full potential of smart factories.

The future of manufacturing lies in the convergence of IIoT, AI, and advanced technologies, creating a highly automated, data-driven, and agile production environment. By embracing this transformation, manufacturers can stay ahead of the curve and thrive in the era of Industry 4.0.

Share

Share